If you are searching for leather work belts made in the USA that is what I do. I make a real 100% USA made leather belt that works great in any work setting (ok except for a suit). The leather, hardware, finish are all made right here. I put all that together myself to bring you a belt that has the right balance of durability and style that you can wear to work or anywhere without a clunky or overbuilt look to it.

What sets my work apart from discount store belts is strong, real, full grain leather that is less likely to stretch, hand applied finish, hand burnished edges, conditioner, and topcoat. The solid hardware and removable fasteners finish this out, all made in the USA. .

Years of trial and error in making belts and all types of leather goods moved me towards the end result, leather work belts made in the USA that look great and are designed to hold up to whatever you do for a living. You can buy it right here and I offer free shipping and a leather care guide that takes the guess work out of your purchase.

3 REASONS WHY A LEATHER WORK BELT MADE IN THE USA IS IMPORTANT

The first reason is you will be supporting all your fellow American workers who make all the parts and pieces used to make this happen-all 100% made here.

The second is no matter how physically demanding your work is (or isn’t) this belt is real leather and will hold up better/perform better/look better than any cheap department store belt.

The third is with our casual lifestyles thoughtfully designed leather work belts made in the USA will look nice enough for almost any function.

WHAT RUINS A BELT-WHY YOU NEED A LEATHER WORK BELT MADE IN THE USA

Poor quality leather fails easily and is not the best choice for a work belt.

If you are engaged in hard physical labor all week or you sit a lot you can just as easily ruin a cheap belt. Movement/your physical activity, moisture/through sweat and melding/constant forces against your leather all come into play.

Movement-Your everyday activity, every move your belt flexes. Your belt also has to carry your pants along with everything in them-at least 2-4 pounds of fabric and stuff like your phone, wallet, keys, knife…

Moisture- Daily 24/7 365 exposure to sweat will ruin any belt, if you work in a hot factory or construction on the equator or our hot and humid Midwestern and Southern states then a nylon riggers belt might be your best bet. A leather work belt made in the USA will hold up better than a cheap one in that situation but will eventually stretch and fail. Yep, I am a leather guy telling you leather is not always the answer. You need both actually, drying a leather belt between use and conditioning it correctly can help and are spelled out in my guide.

Melding-The crossroads of movement and moisture are actually techniques used in other areas of leather working but really bad for a belt. Wetting and shaping veg tan leather once will mold it into tight-fitting knife sheath or gun holster with retention qualities. Keep repeating that wetting/sweating and stretching process and you cause problems, cracks, stretching, thinning and eventual failure.

Here is where added weight comes into play. If you are overweight like me take your current belt off and lay it flat. You will notice is has a bow shape to it. That is because the belly pushes it down in the front. It has more stretching along with downward force to contend with. A firm superior grade of leather can help mitigate that-it will still happen but not as soon.

Buy a good leather belt (of course) but know its limitations. Lack of proper care can also damage a belt or doom it die an early death of neglect. My free leather care and selection guide can help with the maintenance part.

GET YOUR FREE LEATHER CARE AND SELECTION GUIDE !

BUY AMERICAN, THE QUEST FOR THE USA MADE LEATHER BELT

Our 100% American Made Leather Belt. Tan with black edges and buckle.

When I started looking for all the materials required for leather work belts made in the USA I found out there are not many tanneries or hardware manufacturers in America. I felt it was important to support the ones that are still doing business. There are many factors that led to the demise of manufacturing in this country, but each job lost or saved represents a real person, a real family, a real community. Then there is the ripple effect each time a job is lost. Not everyone is made to work at a desk or in front of a computer screen, people still want to work with their hands and make things.

While we think of the shake out of US based manufacturing as a thing that occurred in the past, unfortunatly it is ongoing. Even recently as the Summer of 2020, a difficult year for many businesses, a US based tannery closed its doors in Hartland Maine affecting 115 workers and impacting an entire town.

Source/Article: www.centralmaine.com May 5 2020 Hartland tannery to close by summer’s end, leaving 115 out of work.

With the American leather industry still loosing jobs I know supporting US companies is the right direction for me. It is easy to say “Buy American” but you have to make the case, prove the value and put a solid win in the “why Buy American” column.

WHY A USA MADE LEATHER BELT IS THE BEST VALUE

A US based tanner is the first stop if you are going to have leather work belts made in the USA. This is where a careful, slow (over a month) and technologically superior process using the best available materials and hides makes all the difference. The end result is a leather that is firmer and less prone to stretching than a cheaply produced import leather. Tanning is a word derived from tannins that are found in tree bark. This age-old process has been refined over the centuries but essentially uses the tannin immersion our pioneer forefathers would recognize to produce a strong durable leather that has all the qualities we need in a belt leather. It is important not to confuse this with other processes that produce thin flexible jacket/bag/couch leather-completely different stuff.

Beveling edges so they end up rounded, burnished and smooth

What is full grain leather? It is a leather hide, hair removed, then tanned. The beautiful smooth side (called the grain side) that you see, and finish is not modified in any way. Any natural variation can show and add character. This again would get the nod from our pioneer ancestors because it is the strongest form a veg tan leather out there and the type they used. The only alteration might be to reduce the thickness which is done from the inner/suede like (flesh side) side only.

If we were able to nano particle ourselves and get down past the smooth durable surface of the leather, we would find ourselves in a twisted maze of fibers that makes up the body of our full grain vegetable tan belt. The smooth outer surface area locked in with the twisted inner fibers are what make full grain vegetable tan leather the best choice for single ply leather work belts made in the USA. Another advantage of a single ply belt made from a solid piece of real leather is that the inner surface of the belt is very grippy which keeps your belt in place.

This is full grain vegetable tan leather, you can see the twisted mass of fibers and smooth outer area which together form the best leather for a work belt.

TYPES OF “LEATHER” TO LOOK OUT FOR WHEN LOOKING FOR LEATHER WORK BELTS MADE IN THE USA

I have a free guide the covers leather in detail but added some of the most important right here in the article. These are leather types you will want to avoid when looking for leather work belts made in the USA. The two worst are the bonded leather sawdust/particle board stuff you find at a discount store and “genuine” leather.

DOWNLOAD YOUR FREE LEATHER CARE AND SELECTION GUIDE !

BONDED LEATHER-OK FOR A CHEAP COUCH NOT A LEATHER WORK BELT MADE IN THE USA

If you hear the word “bonded” it is basically leather fibers pureed and then pressed into a sheet. Ok for a cheap leather couch, not ok for a heavy-duty belt. Bonded leather can be combined with “genuine” leather and or manmade materials to produce something the maker gets to call leather but its not a good lasting type and will fail.

GENUINE LEATHER IS NOT GENUINE IN ANY WAY

Genuine means taking the split off remain of real leather from the back of the hide (the fibrous suede like area) and fusing it together with and new topcoat/surface made from “other” items to technically be considered leather. Without the support and strength of the real outer area of full grain leather this will easily fail under work conditions.

INVEST IN QUALITY AND YOUR COUNTRY

Unlike your typical import discount store merchandise real leather work belts made in the USA will easily bounce back from hard use and provide years of use and pride of ownership. No matter what work you do from the field to the office a full grain leather belt made right here will work right along side of you. Check it out and get one started today.

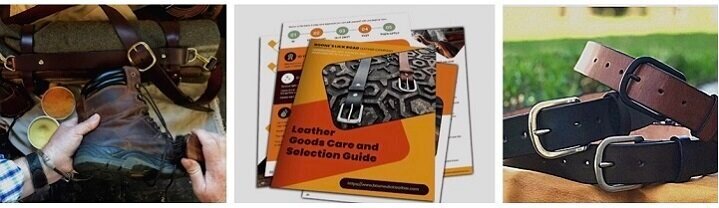

From left to right, dark brown with matte nickel, light brown with black buckle and edges, black with nickle buckle.